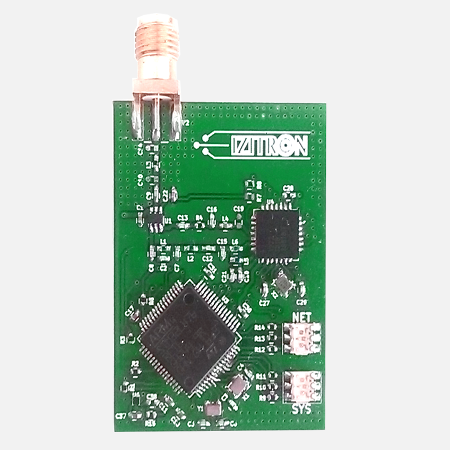

HARDWARE DEVELOPMENT

Hardware architecture, Electronic schematics, PCB routing, BOM, Bench-Test

EMBEDDED SOFTWARE

Low - level programming (C/Assembler), Driver development, Multi-task RTOS programming, Software architecture development

SYSTEM CORES

Architecture ARM Cortex M0/M4/A7/A9, Atmel AVR, Microchip PIC, TI MSP430, Tensilica Xtensa LX6/LX106, Lattice FPGA

RF COMMUNICATION

Wifi, BLE, LoRa, DigiMesh, Sigfox, NFC, RFID, GSM/GPRS

COMMUNICATION PROTOCOLS

UART, USB, RS232, R485, ARINC, TCP/IP, UDP, CAN, I2C, SPI, DALI

TECHNOLOGIES & PLATFORMS

Linux Kernel/RT, uClinux, FreeRTOS, NuttX, Olimex, Raspberry Pi, Arduino, MachXO3L